Summary

This business model canvas is written about the facilitation of turning restaurants organic waste into custom ass plant pots, 3D printed from the bioplastic PHA and filled with compost that are both composed out of the organic waste. Restaurants, and especially restaurants that cook with either food waste like Instock does, or fully or partly vegan with home grown vegetables like MediaMatic, de Ceuvel and de Dakkas do, produce relatively large amounts of food waste. At the same time, these are especially the restaurants that highly value sustainability and do not have access to the public vegetable, fruit and garden (VFG) waste separation because this is non existent in Amsterdam.

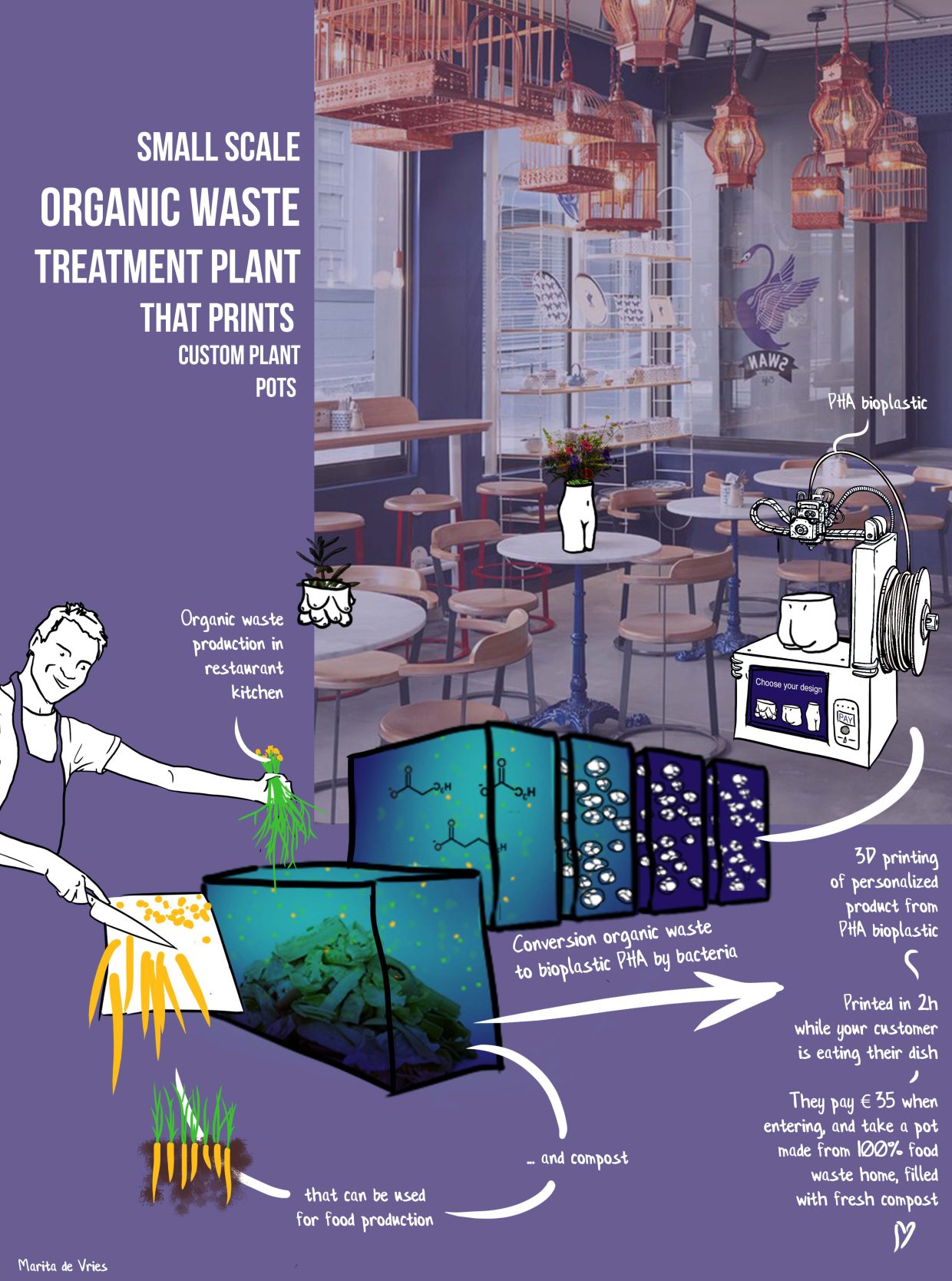

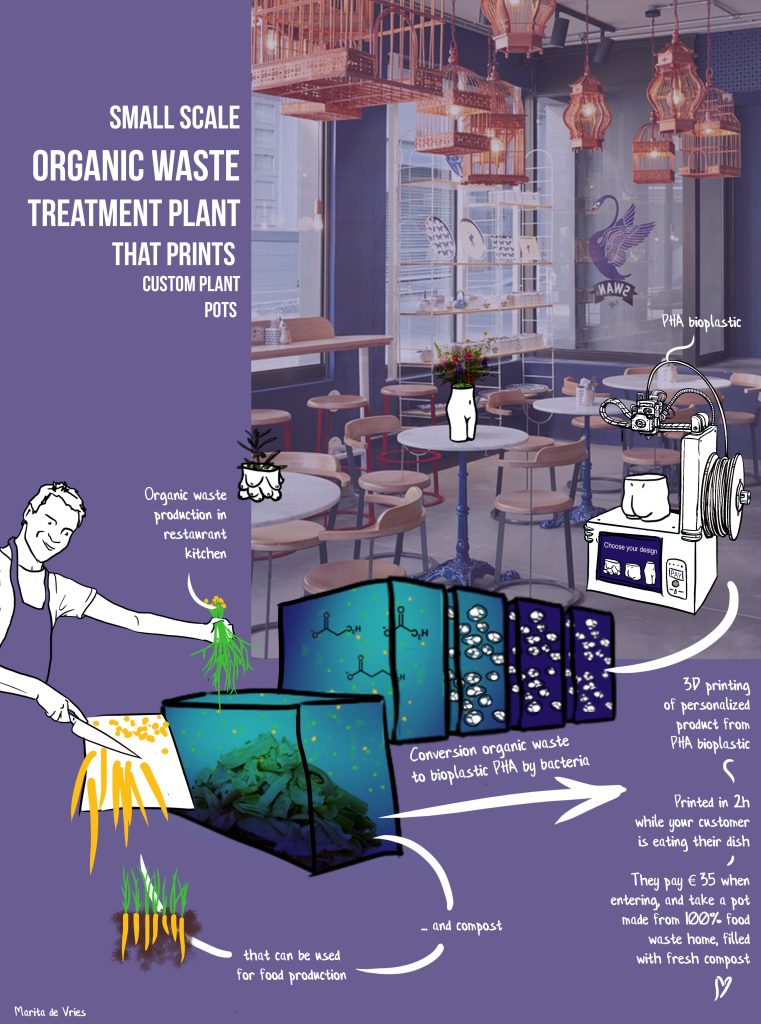

My idea is to offer the service of a small-scale organic waste treatment plant to these restaurants, and at the same time offer an attractive, fully circular and personalized product that is 3D printed from the bioplastic PHA that is made in the little organic waste treatment plant, to the customers of the restaurant. All of this will be offered as a service to lease on a monthly basis by the restaurant. The service includes delivery, installation and maintenance (ideally by bike) of the system as well, which makes the effort investment for a restaurant very small thus the accessibility high.

The bioplastic PHA is produced by first grinding the VFG and adding water to it that the volatile fatty acids (VFA) will resolve into. The water is filtered off together with the VFA’s. Special bacteria will convert VFA into the bioplastic PHA. 1 ton of VFG makes about 37.5 – 75 kg PHA. What we need for this process fits in four large boxes in a row and some pumps. Besides bioplastic, the solid organic waste left after extracting the VFA-containing water, is turned into compost. Also home-produced compost is highly valuable for a sustainable restaurant. The visualization on the left shows the production process, with the human rounded plant pots as output.

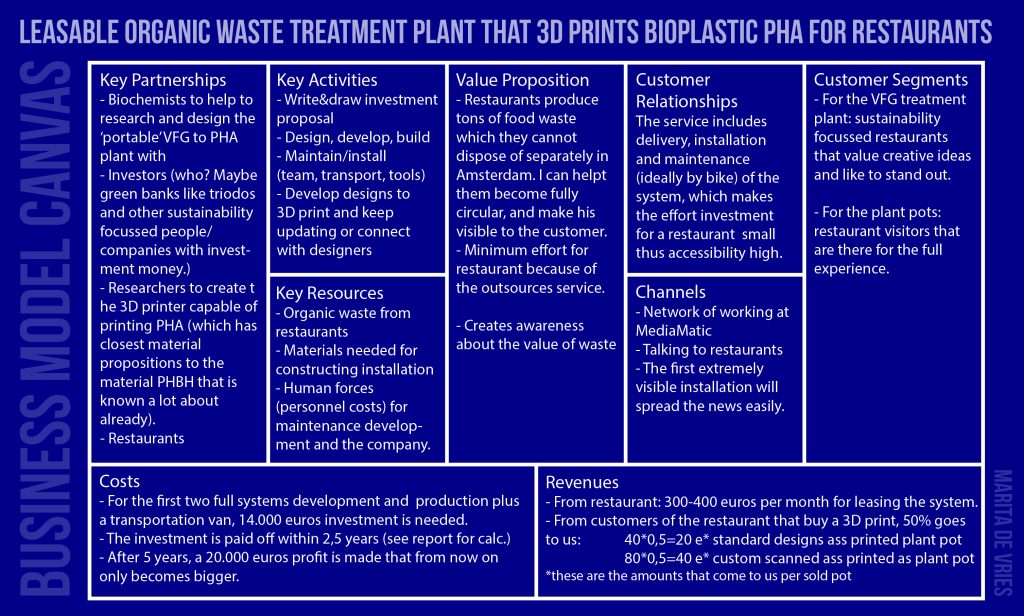

Business model canvas

Figure 1 shows the business model canvas for the organic-waste-into-bioplastic-to-3D-print-treatment-plant. The main topics herein are explained more elaborately. Also three interviews are executed, with the scientist working on the development of the bioplastic production methodology, with a sustainability focussed restaurant owner and with a potential customer.

1. Customer segments

The customers of the LitterLaceLamps producing waste treatment service, are sustainability focussed restaurants that value creative ideas and like to stand out. A higher price range restaurant would be most interested because their customers might be most interested in the relatively expensive LLL’s with a high level of sustainability and aesthetics.

- For the VFG treatment plant: sustainability focussed restaurants that value creative ideas and like to stand out

- For the LLLamps: restaurant visitors that are there for the full experience

2. Value proposition

I would like to make people aware of the value of waste. Clear and educative visuals on the installation will make the plant look appealing and attract interest. Restaurants produce tons of food waste which they cannot dispose of separately in Amsterdam. Restaurants are doing a great job in their sustainability, but a huge gap in becoming fully circular is the VFG treatment. The little treatment plant is designed in a way that makes the process very clear. This will result in more awareness that this restaurant is doing a good job and therefore attract more customers.

The value proposition of the ass plant pots is the differentness that makes it stand out and personalization that can be done through 3D printing it while you eat your meal. Someone chooses the specific product when arriving, and the print can be made in a couple of minutes to hours (to even days), dependent on size and complexity.

Also the customer can directly see the source of the material. The organic-waste-into-bioplastic-to-3D-print-treatment-plant can of the material and that it does not harm finite resources, something highly gaining popularity nowadays.

3. Revenue streams

- Leasing the VFG treatment plant generates a monthly fee income. Jeroen (see interview 2) who owns restaurant De Dakkas, said that 200 euros would be not much, and 300-400 euros would be doable still. To shorten the payback time of the investment of developing and building the whole system, the price will be between 300 and 400 euros per month to lease for the restaurant.

- Fundraising/investment seeking has to be done in order to make production of the little treatment plants possible in the beginning.

- Restaurant customers pay for their printed product, the ass plant pots, of which half goes to the restaurant owners, and the other half comes back to our income too. The standard plant pot variations will be valued at 40 euros, and come with a bit of homemade compost as well as a chosen herb inside. If the technique is ready, ideal would be have the technique available to scan your own ass and have that printed into an extremely personal plant pot. However, this will require a lot of technique and make the pot twice as expensive, namely 80 euros.

4. Channels

I will make attractive visualizations of the whole process including the value propositions, and have nice conversations with the restaurant owners. Most of the above-mentioned ones I know already (indirectly) and would be easy to reach. Once this extremely visible installation is placed at one place, it can start travelling via word of mouth and even festivals would be a great location, where it will receive a lot of attention.

5. Customer relationships

The service includes delivery, installation and maintenance (ideally by bike) of the system, which makes the effort investment for a restaurant very small thus the accessibility high.

6. Key activities

- Write&draw investment proposal

- Develop the ‘portable’ installation(s) with invested money

- Keep a maintenance/installation team on the road

- Have and maintain a large enough bakfiets to transport all

- Develop designs to 3D print and keep updating this (or connect with designers)

7. Key resources

- Organic waste from restaurants

- Materials needed for installation

- Human forces (personnel costs) for maintenance and delivery

8. Key partners

- Biochemists to help to research and design the ‘portable’ VFG to PHA plant with

- Investors (who? Maybe green banks like triodos and other sustainability focussed people/companies with investment money)

- Researchers to create the 3D printer capable of printing PHA (which has closest material propositions to the material PHBH that is known a lot about already). The first prints have now successfully been made.

- Restaurants

9. Cost structure

OUT

- Initial investments 14.000.

- Developing and producing first installation(s). An estimation is made that the development of the system due to the people that need to get paid for their knowledge and practical skills, as well as the tangible materials to build the system, will cost 5.000 euros. On top of that a 3D printer costs 1.000. The investment of the first two organic-waste-into-bioplastic-to-3D-print-treatment-plant that will be used for the calculation, is 2×6.000=12.000 euros.

- Transport by van: 2.000 euros.

- Ongoing costs personnel:

- Transport & install machine 2 times per year, taking 8h on average for 25e/h, makes 400e/y.

- Check system, estimates on an average of monthly.

- 4h, including transport. 4x12x25= 1200e/y.

IN

- Two restaurants pays 400 e/month, for 10 months. Estimated is 10 months using each system per year, because it is possible that there are months in between restaurants and maintenance times. That makes 400x2x10= 8000 e/y earned by leasing.

- At first, only standard designed plant ass and boob pots are available (as seen in figure 1). These are prices on 40 euros, of which 50% goes to the restaurant and 20 euros are earned by us per lamp. Estimated is 10 sold lamps per month per restaurant, which gives 20x10x2= 400 e/y on pots.

TOTAL

- 400 euros spent on installation and delivery of the systems, can be erased against 400 euros coming in from the sold plant pots.

- Calculating the time it takes to earn the investment money back, while personnel costs keep on existing in a year, gives a 2 years and a month time that it takes to earn the investment money back when having two total systems on the market. After five years, there is (14.000+2×1.200=) 20.000 euros spent, and (5×8000=) 40.000 euros earned, which gives a profit of 20.000 euros after the first five years . From there on the profit will only become bigger if the systems do not become outdated already. This is partly dependent on the plans for central organic waste treatment in Amsterdam.

Interviews with bioplastic researcher and restaurant owner

Peter Mooij is researcher in the FABULOUS (Fatty Acid Biorefinery for Upcycling Low-value Organic Urban Substrates) project, where the production process for transforming GFT into the bioplastic PHA is defined. Peter is also my thesis supervisor and told me a lot about the process. For this business idea, I asked him whether these techniques could be applied already and part of the investigation was to go visit the treatment plant that they now built at OrgaWorld in Lelystad (figure 3).

In OrgaWorld I could see the small scale treatment plant that the FABULOUS project group built as a test set-up. In here, 1 ton of VFG makes about 37.5 – 75 kg PHA, which also is the amount that the set-up can treat per week at this moment. In the second interview, Jeroen tells me that De Dakkas, his restaurant would by far not produce that much waste, resulting in the estimation that the treatment plant itself would fit within a 5m2 ground surface area. I told Peter what the idea is and he said that all necessary techniques are available right now.

Jeroen Spek is the owner of De Dakkas in Haarlem, a sustainability focussed restaurant that serves mostly organic food and drinks and produces vegetables themselves as well. The Dakkas is located on the roof of an office building. De Dakkas originated from sustainable urban principles and has the communication of these as a main driver for running the restaurant, Jeroen tells me on the phone.

Jeroens main concern is the marketing and slikness of the system. For him the actual function has to stay more important than selling the product and the green image. This is a point of view that I like a lot and want the systems to be as well. Therefore a clear visualization of the full systems LCA (life cycle analysis) should be made.

I asked Jeroen some questions:

Do you already recycle organic waste and in which way?

- No, not yet but we want to. Composting is the intention. We now have 6 chickens and bee hens on the roof. There is a Rocket worm hotel system that we look at the moment that can treat 75l per week only. That is not enough.

Do you like the idea of an external organic waste treatment plant that turns GFT into bioplastic PHA and compost?

- I want to make the food chain visible for the audience, and really like the idea of the treatment plants because it can help me in my goal to inspire people in a positive way. It shows the customer how things can be done differently and fit at De Dakkas because it puts soul into the business.

What do you think would be most potential to print? I have been thinking of pattern lamps, candle holders, balcony tables, special mugs or plant pots with boobies. Jeroen looks at my visualization (figure 2).

- I like the plant pots because they can also store the compost that we produce. Until now the idea was that we can give the customers a small bag with compost home after their visit, which is in line with your idea. I like to have a strong connection with the neighbourhood. By giving outstanding plant pots, the customer journey reaches all the way home.

Would you be willing to pay 200 euros per month for this system including leasing?

- Composting is a big goal of mine that I want to spend money on anyways, so it would not be too much and could even be a bit more. Leasable is a good idea, for in case it turns out to be disappointing.

Do you have 5m2 space for a VFG treatment system?

- That is not a problem for us. The total area is 650 m2, 350 terrace, 300 greenhouse.